To ensure that wastewater is safely conveyed and that buildings and surrounding areas are reliably protected against flooding, powerful and durable pumping technology is required. Our wastewater lifting and flood control pumping stations combine state-of-the-art technology with proven design.

They ensure smooth and reliable operation – even under high flow rates, challenging installation conditions, or extreme weather.

Description

Archimedean Screw Pump

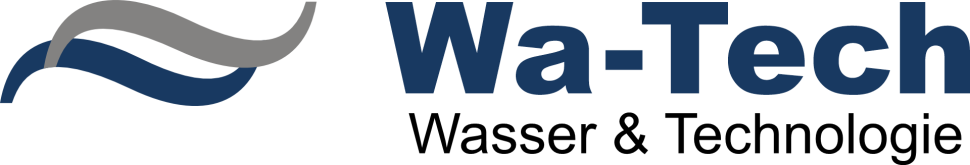

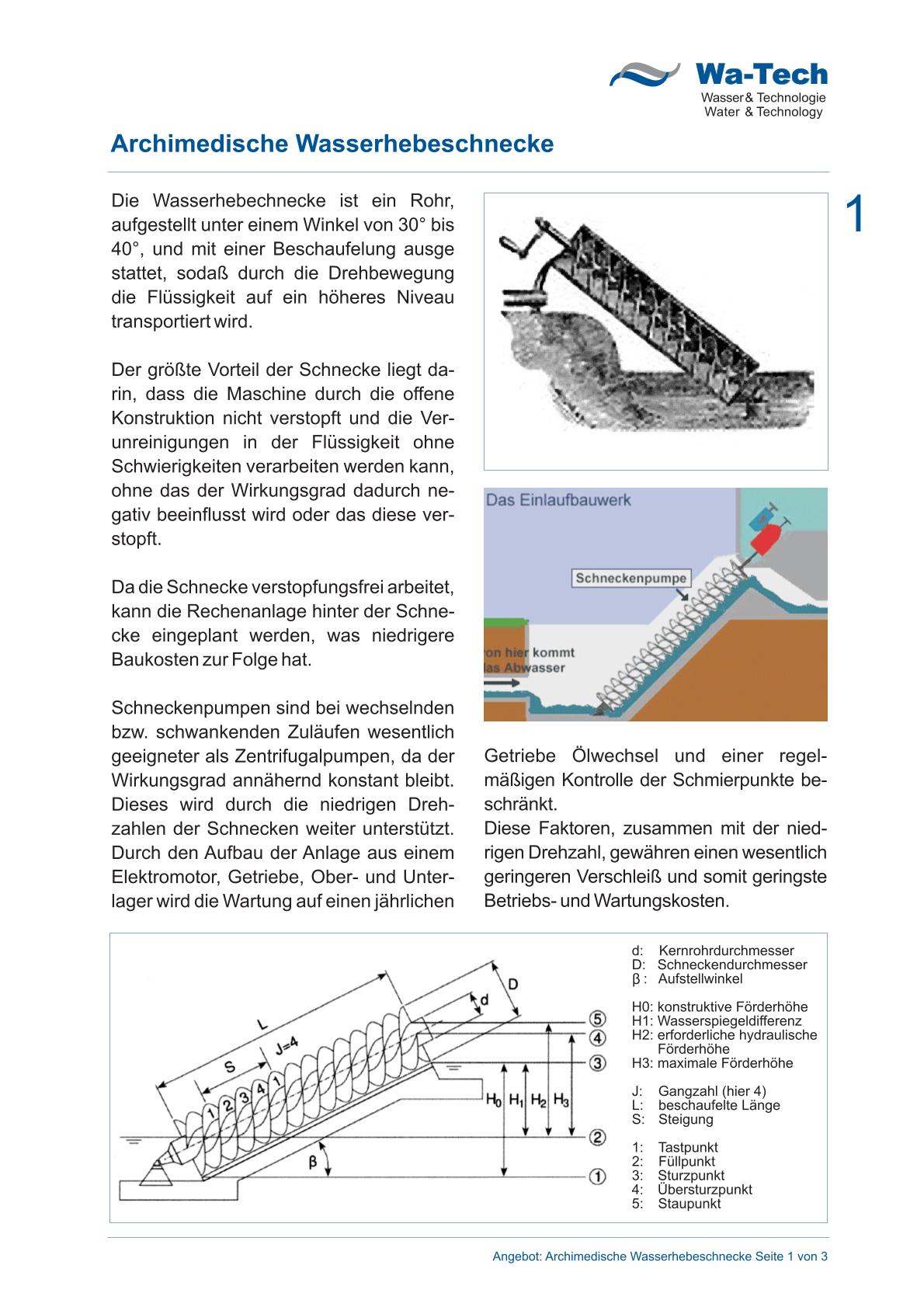

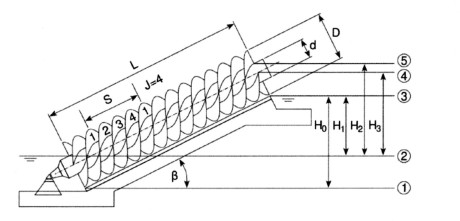

The Archimedean screw pump consists of a tube installed at an angle between 30° and 40°, equipped with helical blades. Through rotational movement, it reliably transports liquid to a higher level.

Maintenance and Operation

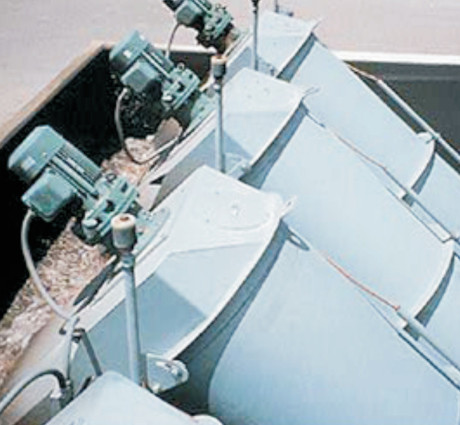

The low rotational speed of the screw ensures minimal wear. The system consists of an electric motor, gearbox, and upper and lower bearings. Maintenance is limited to an annual gearbox oil change and regular inspection of lubrication points. This results in minimal operating and maintenance costs.

Designs and Versions

Different variants are available for the trough design:

-

Concrete trough: The screw is inserted into the trough using a special mortar at low rotational speed. Alternatively, a steel shuttering template can be used, which is removed after grouting.

-

Steel trough: Remains embedded in the concrete after grouting.

-

Self-supporting steel trough: Fully prefabricated at the factory (trough, bearings, drive) – allowing for short installation times.

-

Tube screw: Features integrated upper and lower screw bearings connected to the outer tube. Due to its self-supporting construction, no fixed connection to the concrete structure is required – the simplest and fastest installation of all types.

Advantages

Advantages and Applications

The greatest advantage lies in the open design

The screw pump does not clog and can easily handle liquids containing impurities – without any loss in efficiency. Since the screw operates without blockages, the screening unit can be installed directly downstream, which allows for lower construction costs.

In addition, screw pumps are better suited for fluctuating inflows than centrifugal pumps, as their efficiency remains nearly constant.

Gallery

Storage

Bearings

Upper Bearing – Versions

- Lubrication via oil reservoir: With wall mounting (against concrete or hydrostatic pressure). A cast steel support is not required.

- Base mounting: Onto concrete or a cast steel support.

- Self-supporting (tube screw): No concrete required.

- Lubrication: Via grease nipple, pneumatic, or electric system.

Base Mounting

In this design, the bearing support is installed on the site-provided concrete base and then aligned. The outer tube with the lower screw bearing absorbs radial and axial forces (X-bearing type). The design is watertight and maintenance-free, featuring oil counterpressure lubrication (tube screw).

Self-Supporting

In this version, the bearing support is formed by the outer tube of the screw pump itself. Therefore, no concrete work is required. The outer tube with the screw pump is suspended from the site-provided crossbeam.

If adjustments to the screw’s height position are required due to changing water levels, this can easily be achieved by shortening the suspension length.

Lubrication via Oil Reservoir and Hydrostatic Pressure

This design eliminates the need for additional electrical or pneumatic connection lines or monitoring systems.

Downloads

Downloads