High-efficiency sand washing and separation

The SAW reliably removes organic components from sand and ensures thorough dewatering. This improves the quality of the sand, relieves downstream processes, and increases the operational reliability of the treatment plant.

Description

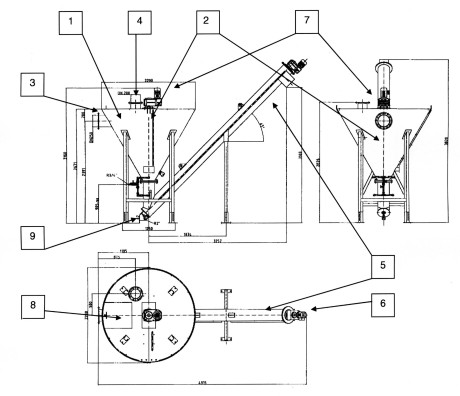

Sand Washer SAW

Purpose of the System

The sand washer is designed for the separation and dewatering of easily settleable solids, featuring an integrated washing unit for the removal of organic substances.

Design and Technology

The sand washer consists of a combined washing and settling tank with an integrated mechanical agitator, inlet and outlet pipes, and a shaftless screw conveyor positioned at a 45° angle beneath the washing trough.

The screw conveyor drive is located at the upper end of the discharge spiral (pulling configuration), eliminating the need for submersed bearings. To reduce maintenance costs and effort while increasing service life, the discharge conveyor pipe is equipped with extra-high wear-resistant liners. These also ensure smoother operation and longer replacement intervals.

The agitator is also mounted directly on the drive motor, making submersed bearings unnecessary. All drives are positioned for easy maintenance access.

Hygiene, Inlet and Outlet

The washing trough is completely enclosed with a bolted cover to ensure a hygienic working environment and minimize the release of gases. An inspection hatch with hinges and a locking mechanism allows easy access for inspection.

The inlet is connected via a flange-mounted pipe at the top of the trough, while the outlet is located at the rear side. Only one inlet and one outlet connection are required, reducing additional piping costs.

Operating Principle

Design and Operating Principle

Washing and Discharge Process

The slowly rotating agitator (low wear) imparts mechanical energy to the sand in the form of movement. This motion, combined with the natural movement of the sand grains, separates adhering organic particles, which are then removed with the wash water over the overflow edge.

After the washing cycle, a preset portion of sand is discharged from the separation hopper. The sand washer is then refilled until the defined fill level is reached, initiating a new washing cycle.

Alternatively, the machine can be continuously fed with a sand-water mixture from the grit chamber. The washing and sand discharge process then operates accordingly.

Adjustments and Optimization

Any desired modifications to existing site conditions are implemented by us to optimize overall costs and machine performance.

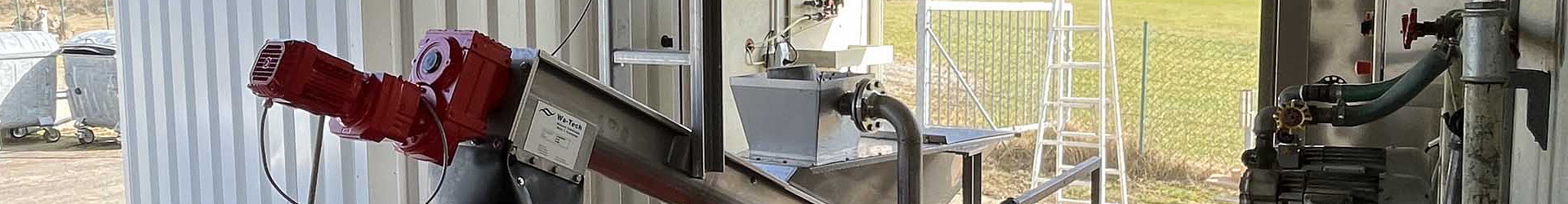

Gallery