Space-saving and efficient cleaning

The KBUR reliably removes coarse solids from wastewater and protects pumps and downstream treatment stages. Its compact design makes it particularly suitable for confined installation situations while ensuring efficient, safe operation of the wastewater treatment plant.

Description

Applications and Functions

For the removal of solid and fine materials such as glass, stones, wood, paper, cosmetic products, cotton swabs, hair, etc., from liquids such as river water, cooling water, wastewater, sludge, chemical and brewery water, return sludge, excess sludge, or sewage sludge, as well as for use as a filter before ultrafiltration.

For advanced air purification, the screen can be equipped with an exhaust air connection for integration into an air treatment system.

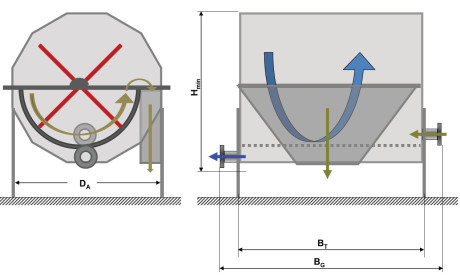

The drive is provided by a separate direct drive, which can be installed on either the right or left side depending on site conditions. Torque is transmitted from the motor to the shaft via a detachable, friction-locked connection (feather key).

Functionality

Design and Operating Principle

The inflow is connected via a flange on the side. The outflow can be positioned either on the opposite side or on the same side as the inflow.

The compact brush-type circulation screen consists mainly of a housing containing a curved screening surface and a central main and drive shaft equipped with cleaning brushes. For hygienic operation, the main screen body is fitted with a half-side inspection flap.

The solids are conveyed across the screening surface by the driven brushes into the discharge hopper. From there, the screenings fall downward by gravity.

Optionally, the discharge chute can be adapted to connect to downstream equipment.

Gallery

Gallery