Efficient solids separation

The BGR screen (curved screen) ensures the reliable removal of coarse solids from wastewater. This protects downstream pumps and treatment stages, prevents malfunctions, and sustainably increases the efficiency and operational reliability of the wastewater treatment plant.

Description

Screen Type BGR

Applications and Functions

For the removal of solid and fine materials such as glass, stones, wood, paper, cosmetic products, cotton swabs, hair, etc., from liquids such as river water, cooling water, wastewater, sludge, chemical and brewery water, return sludge, excess sludge, or sewage sludge, as well as for use as a filter before ultrafiltration.

Maintenance, Drive, and Control

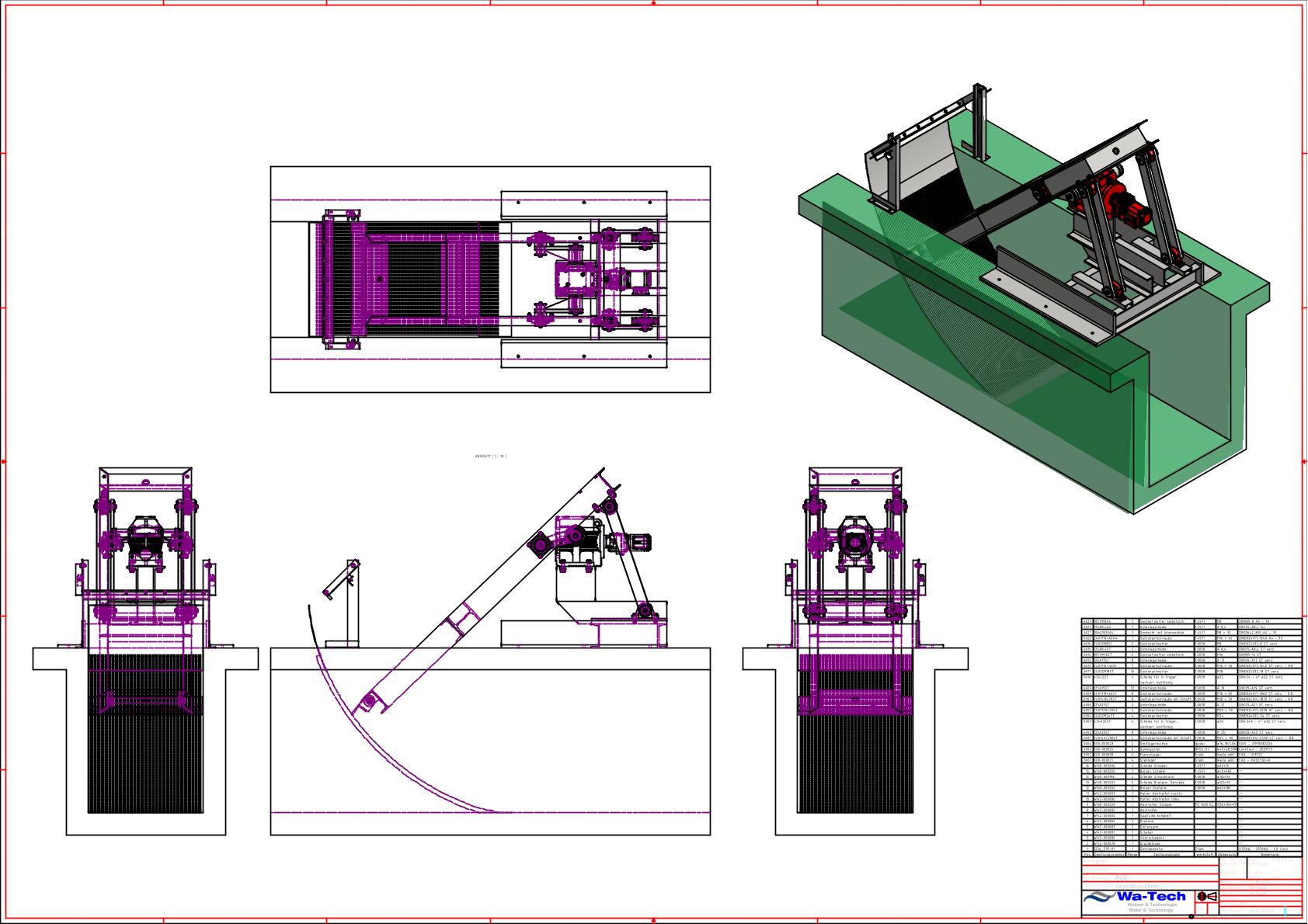

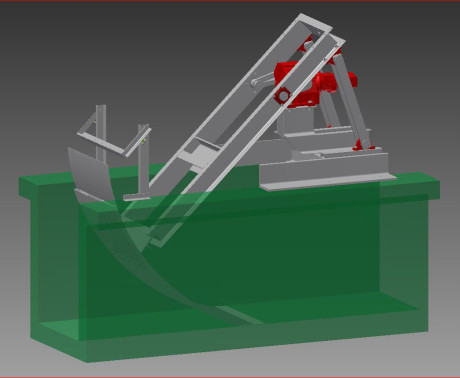

The screen has no moving parts within the channel area, making it highly maintenance-friendly. All bearing units are positioned above the channel surface for easy access. The cleaning scraper or screen rack can be replaced without disassembly. The drive operates via a separate direct drive, while the rake arm system functions mechanically and eccentrically, requiring only a quarter turn per cycle. Control is typically managed by a level sensor positioned in front of the screening surface.

Functionality

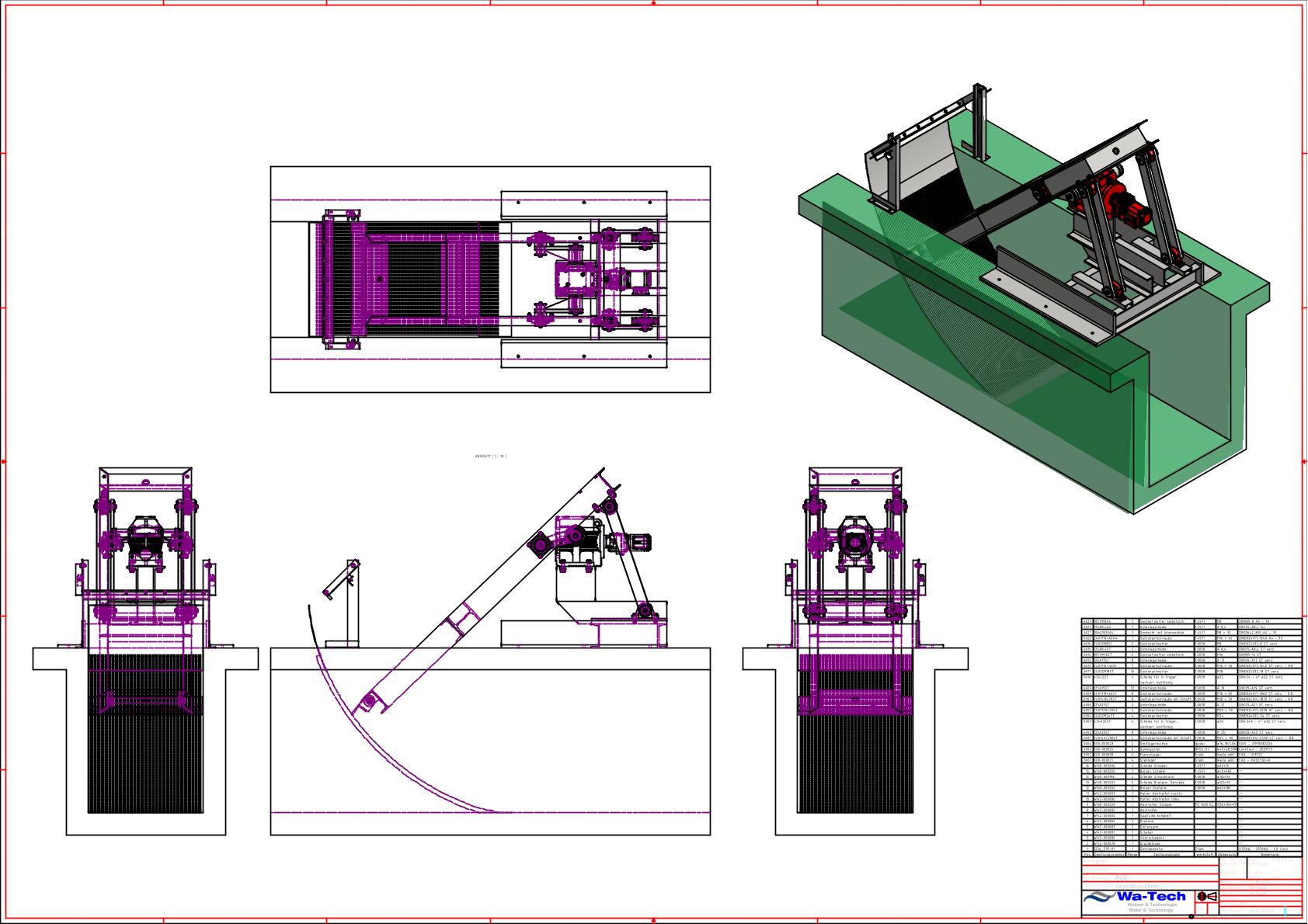

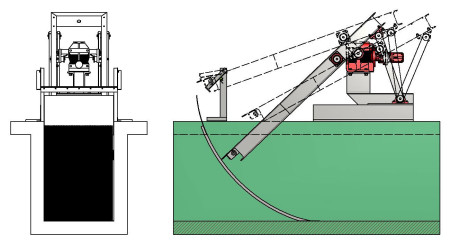

Design and Operating Principle

The curved screen mainly consists of the drive unit with an eccentric mechanism, the rake arm equipped with one or more cleaning scrapers, and the screen rack. The cleaning scrapers transport the screenings to the discharge chute, where they are transferred to the downstream equipment without the need for a separate drive.

Its robust design, variable bar spacing, and adaptable configurations make it suitable for a wide range of applications, including breweries, paper mills, and installations upstream of turbines.

Advantages

Cleaning Performance and Advantages

The optimized screen shape in the base area increases the screening surface, reduces flow velocity, and enhances cleaning efficiency.

As a result, fewer fine materials pass through the screen, leading to reduced susceptibility to malfunctions in downstream pumps and machinery, as well as minimizing sediment build-up.

Gallery

Gallery

Downloads

Downloads