Robust solids separation

The KURMC screen reliably removes coarse solids from wastewater, protecting pumps and downstream treatment stages. With efficient operation and durable construction, it ensures stable performance and high operational reliability for the wastewater treatment plant.

Description

Applications

For the removal of solid and fine materials such as glass, stones, wood, paper, cosmetic products, cotton swabs, hair, etc., from liquids such as river water, cooling water, wastewater, sludge, chemical and brewery water, return sludge, excess sludge, or sewage sludge, as well as for use as a filter before ultrafiltration.

Maintenance and Drive

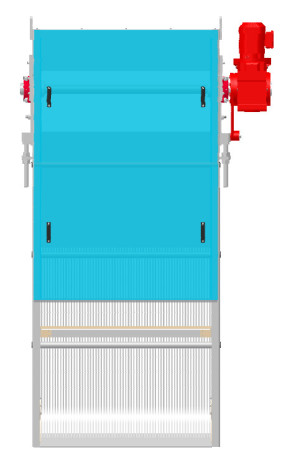

The screen has no moving parts or rotating bearings within the channel area. All bearing and tensioning units are designed for easy maintenance and are positioned above the channel surface and outside the screen frame.

The screenings are discharged through a chute directly into the subsequent machine. Gravity discharge is supported by a cleaning strip installed above the discharge point. Additional cleaning brushes or spray bars are not required. Above the discharge area, the drive sprockets with main shaft, tensioning unit, and bearings are located.

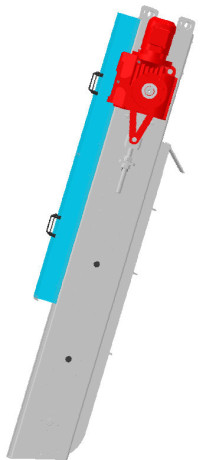

The drive is provided by a separate direct drive, which can be installed on either the right or left side depending on site conditions. Torque is transmitted from the motor to the gears via a detachable, friction-locked connection (feather key).

Functionality

Design and Operating Principle

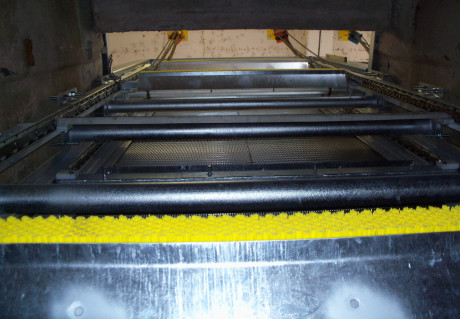

The chain circulation screen consists mainly of two drive chains with cleaning bars, sprockets mounted on the drive shaft, the lower deflection unit, a chain guide on each side, a single-sided drive unit, as well as the chute with discharge section and the screening rack.

The cleaning bars attached to the circulating chains glide over the screening rack and convey the retained material to the discharge chute. The scraper pushes the screenings over the chute into the subsequent machine without the need for a separate drive.

The entire unit can be installed into the existing screen structure without the need for modifications or recesses, significantly reducing reconstruction costs for existing channels and allowing for quick and efficient installation.

Advantages

Features and Advantages

Due to its robust construction with few moving parts, variable screen opening widths, discharge heights, and customizable number and design of cleaning bars, this screen is also suitable for removing materials such as fish, foundry residues, or for use in vegetable processing, breweries, and paper mills.

Screening can be carried out either as a bar screen or a perforated plate version, depending on the configuration of the chain guides and cleaning bars, to fully meet the specific application requirements.

The adapted screen shape in the channel bottom area allows screenings to be captured directly from the channel floor, increasing the effective screening surface. The larger screen area reduces flow velocity and enhances cleaning performance.

This results in fewer fine materials remaining after screening and significantly lowers the likelihood of repairs or malfunctions in downstream pumps and machinery.

Gallery

Gallery