Precise removal of fine solids

The MC fine screen ensures thorough separation of fine solids from wastewater. This reduces the load on downstream processes, protects pumps, and sustainably increases the efficiency and operational reliability of the wastewater treatment plant.

Description

Applications

For the removal of solid and fine materials such as glass, stones, wood, paper, cosmetic products, cotton swabs, etc., from liquids such as river water, cooling water, wastewater, sludge, chemical water, brewery water, and sewage.

Due to its robust construction and variable opening widths (1–50 mm) as well as adjustable hook spacing, this screen is also suitable for removing items such as fish, foundry residues, and for use in vegetable processing, breweries, paper mills, or in front of turbines and ultrafiltration systems.

Drive and Control

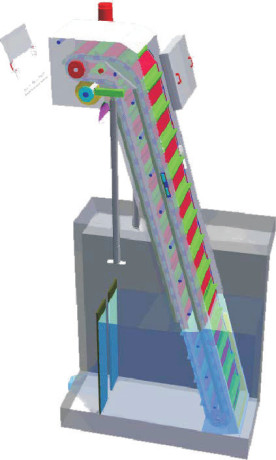

The drive for the screening chain and the cleaning brush is provided by separate direct drives, which, depending on site conditions, can be installed either on the right or left side to transmit torque directly to the drive shaft of the conveyor chains or to the brush shaft.

At the upper point of the sprockets, the retained solids fall off due to gravity, supported by a spray cleaning system. In the discharge area, a mechanically driven brush extending across the entire chain width removes residual solids from the filter belt. To ensure complete cleaning of the filter elements – especially the spaces between them – an additional spray system is installed in the discharge area after the drive wheels, ensuring that only clean filter elements return to the submerged section.

Functionality

Design and Operating Principle

The removal of solids is carried out by a continuous filter belt on which the screenings are gently transported to the discharge point without any relative movement between the screenings and the filter belt.

This process ensures optimal cleaning of both the water and the filter belt. The patented filter belt design allows the block to be removed from the front – enabling a simple block replacement within just 10 minutes.

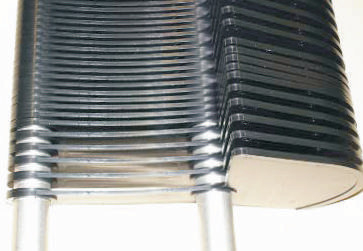

Due to the robust block design with two stainless steel support rods, no central chains or other internal components are required that could cause screenings to become entangled. The filter block consists of two stainless steel support rods and individual ABS elements.

Thanks to the patented construction, there is no movement between the elements or from block to block. As a result, no self-destruction of the elements or the filter belt occurs, even when handling abrasive materials such as sand.

Gallery

Gallery