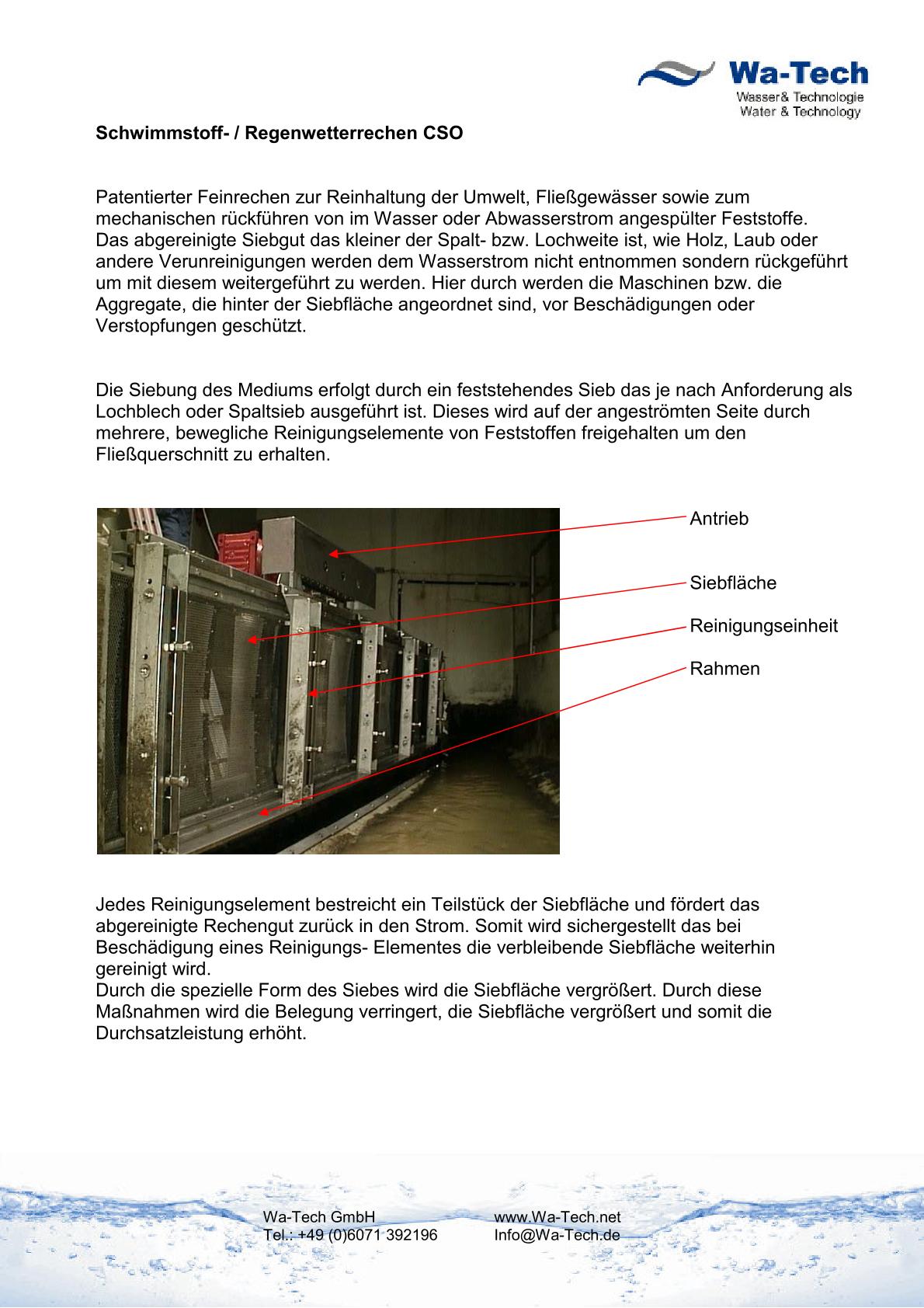

Efficient relief during heavy rainfall

Heavy rainfall causes a sharp increase in the load on sewer networks and wastewater treatment plants. Combined sewer overflow (CSO) storm grates ensure that coarse materials in mixed water are retained before it enters water bodies. Our systems offer reliable protection against contamination, relieve the burden on infrastructure, and make a sustainable contribution to water protection—even under extreme weather conditions.

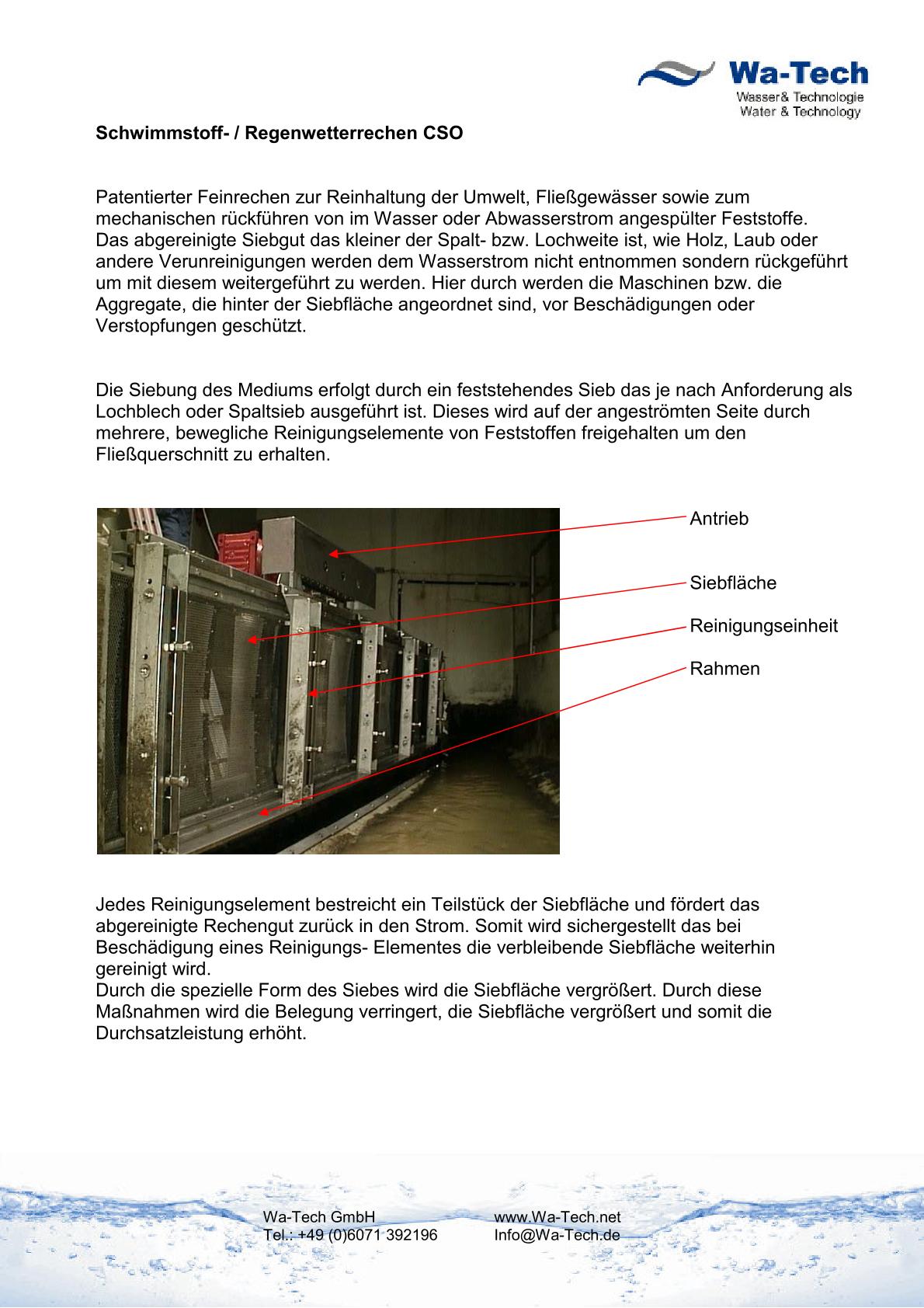

Description

Purpose of the System

The sand washer is designed for the separation and dewatering of easily settleable materials such as sand from wastewater streams. It is equipped with an integrated washing unit that effectively removes organic components from the sand.

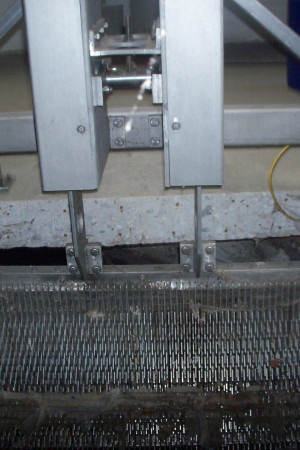

Design and Technology

The system consists of a combined washing and settling tank with an integrated mechanical agitator. Below the washing trough, a shaftless screw conveyor is installed at a 45° angle to discharge the cleaned sand material.

The spiral drive is located at the upper end of the discharge spiral (pulling configuration), eliminating the need for submerged bearings. This reduces maintenance requirements and increases the machine’s service life.

The discharge pipe is additionally fitted with extra-high wear-resistant rails, ensuring smooth operation and extending the system’s lifespan. The agitator is mounted directly on the drive motor, making submerged bearings unnecessary. All drives are easily accessible for maintenance purposes.

Hygiene and Inlet/Outlet

For hygienic operation, the washing trough is completely enclosed with a bolted cover that minimizes gas emissions and protects the surrounding area. An inspection hatch with hinges and a locking mechanism allows easy inspection and cleaning.

The inlet is connected via a flange-mounted pipe at the top of the trough, while the outlet is located at the rear through another flange connection. A drain socket with a shut-off slide valve is positioned at the lowest point of the machine, and no additional organic discharge is required.

Functionality

Operating Principle

The sand-water mixture supplied from the grit chamber enters the separation hopper or washing trough tangentially. Once the sand level reaches a predefined height, the wash water valve opens and the agitator starts. The slowly rotating agitator transfers mechanical energy to the sand particles, causing the adhering organic matter to be released.

The combination of the agitator’s movement and the natural motion of the sand grains ensures that the organic substances are separated from the sand and discharged over the overflow edge with the wash water.

After the washing cycle, a preset quantity of sand is discharged, after which the hopper is refilled and a new washing cycle begins. Alternatively, the system can operate continuously, with the sand-water mixture being constantly supplied and the discharge taking place accordingly. The resulting press water is returned via drainage screens to the collection trough, ensuring that organic components are recirculated.

Advantages

Advantages

The system stands out for its particularly gentle operation: a slowly rotating agitator minimizes wear and thereby increases the service life of the components. At the same time, it ensures effective cleaning by reliably loosening and separating organic matter from the sand. Maintenance is straightforward since all bearings are installed outside the submerged area, providing easy access for inspection and servicing.

In terms of hygiene, the design sets high standards: a bolted cover and an inspection hatch prevent the uncontrolled release of gases and dirt. The durable construction with wear-resistant liners in the discharge pipe and high-quality components ensures long service life and sustainably reduces operating costs. Furthermore, the system offers flexible application options – it can be operated in both batch and continuous modes, depending on the specific plant requirements. Thanks to a well-thought-out design with only one inlet and outlet, it is also highly cost-efficient, as no additional organic discharge is required.

Gallery

Downloads

Downloads