Cleaned Screenings Efficiently Dewatered

The BSWP reliably removes organic residues from screenings while simultaneously dewatering them. This reduces volume and weight, simplifies disposal, and increases the operational reliability of downstream treatment systems.

At a Glance

- Screenings washing unit for the continuous removal of organic material and faecal matter from raw screenings.

- Subsequent compaction and dewatering of the remaining material with discharge onto further conveying systems or into collection containers.

Available Versions:

- BSWP 20

- BSWP 30

- BSWP 40

- BSWP 50

Accessories

Accessories attached to the screenings washing press:

- Guide rails: In the conveying and pressing section, with replaceable dewatering screens

- Wash water supply and rinsing: Wash and press water collection tray with solenoid valve R 3/4" – 220 V/50 Hz and dirt filter (mesh width 0.8 mm)

- Manual shut-off valve: R 3/4"

- Rinsing water connection: With hose nozzle R 3/4"

- Support frame: Adjustable installation frame to compensate for structural tolerances (adapted to the system)

- Press tube: Flanged to the main unit via a press bend for discharge into a container or subsequent conveying systems

- Water/press water outlet: Via flexible hose (L = 2.0 m) or plastic pipe, connected to the existing building drainage system or recirculated into the channel

Materials

Materials

| Conveyor trough, base frame, cover: | see offer |

| Shaft and conveying/pressing screw: | St-52-3 |

| Mixing blades: | Hardox |

| Trough lining in conveying and pressing section (wear rails): | Hardox |

| Trough lining in feed and washing section: | none |

| Drive shaft: | Steel |

| Water pipes: | Stainless steel 1.4571 |

| Connecting elements and moving parts (bolts, nuts, pins, etc.): |

Stainless steel A4 |

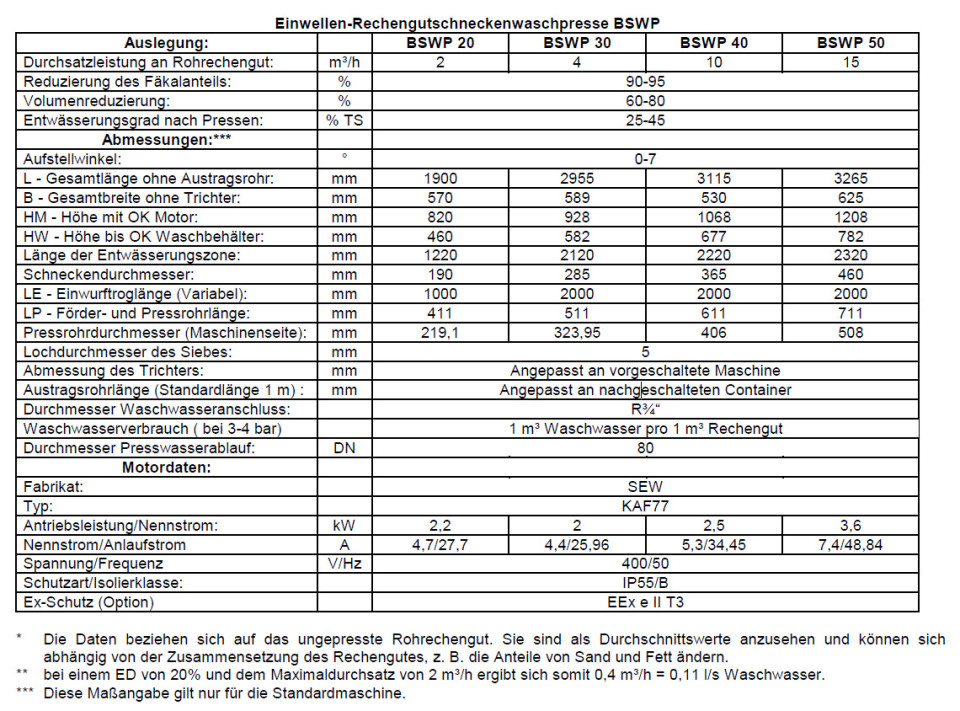

Technical Data

Technical Data

Description

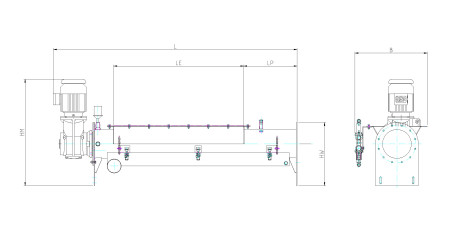

Single-Shaft Screenings Wash Press BSWP

Washing Process

Screenings Washing Plant

The screenings washing plant continuously washes out organic material and faecal matter from raw screenings, followed by compaction and dewatering of the remaining solids, with subsequent discharge onto further conveying systems or into collection containers.

The introduced raw screenings are conveyed into the washing and conveying tube. At the feed section, a wash water connection is located on the upper side and a drainage screen on the underside. The wash water valve is operated simultaneously with the conveying screw.

The wash water containing the dissolved organic matter passes through the drainage screen into a collection trough and is returned to the inlet or building drainage system.

To extend the washing time and improve washing efficiency, the screw conveyor operates alternately in forward and reverse mode.

Pressing Zone and Dewatering

The undissolved material is conveyed by the screw into the downstream pressing zone and friction pipe. Here, the screenings are compacted and dewatered by the counterpressure in the press pipe.

The resulting press water, which still contains organic components, is drained through the front screen into the collection trough and recirculated.

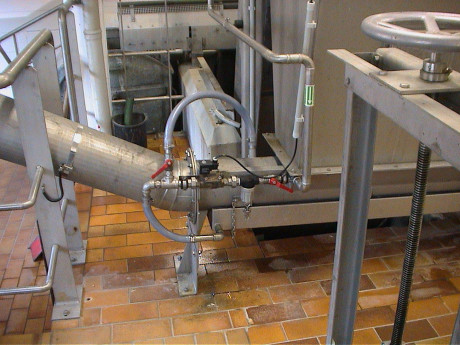

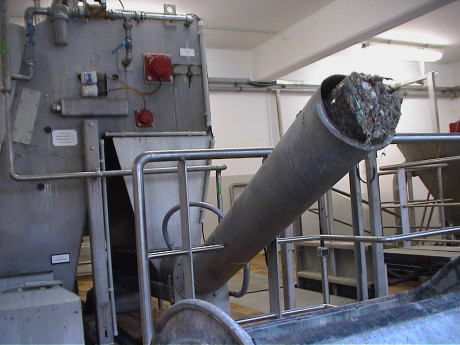

Gallery

Gallery

Downloads

Please contact us directly so that we can provide you with the requested documents and suitable accessories.

Downloads