Screenings press for continuous dewatering, compaction, and transport of screenings

The SP spiral press reliably dewaters screenings, reducing volume and weight. This lowers transport costs and disposal expenses while increasing the operational reliability of downstream systems.

At a Glance

At a Glance

- Screenings press for continuous dewatering, compaction, and conveying of screenings

- Clog-free operation thanks to the pushing drive unit, shaftless spiral, and open spiral end

- Extremely robust conveying and pressing spiral with a length of up to 10 m

Available Designs

- SP 160

- SP 215

- SP 240

- SP 315

- SP 360

Accessories

Accessories Mounted on the Screw Press

- Pre-dewatering zone: With stainless steel perforated sheet drainage, without surrounding spiral brush in the perforated area.

- Drip water collection tray: With drain connection, mounted in the area of the gear motor (optional).

- Piping: 3/4" connection on the machine with rinse water fitting for hose nozzle R 3/4" and manual shut-off valve (optional with drip water collection tray).

- Water outlet: Via flexible hose (L = 2.0 m) or plastic pipe, with connection to the existing building drainage system or return to the channel (optional with drip water collection tray).

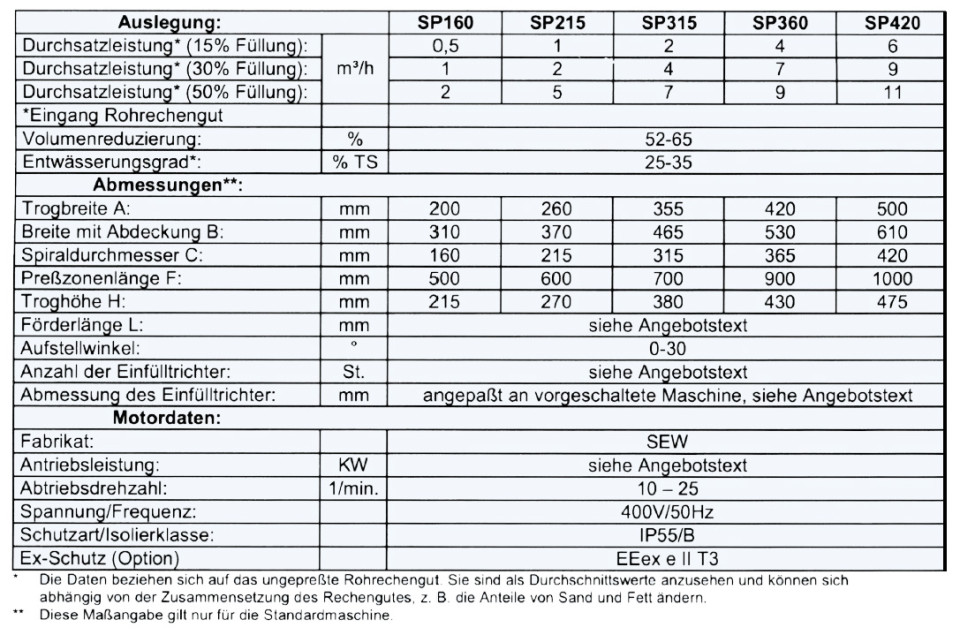

Technical Specifications

Technical Specifications

Description

Screw Press SP

Screenings Press – Continuous Dewatering, Compaction, and Conveying of Screenings

Function and Design

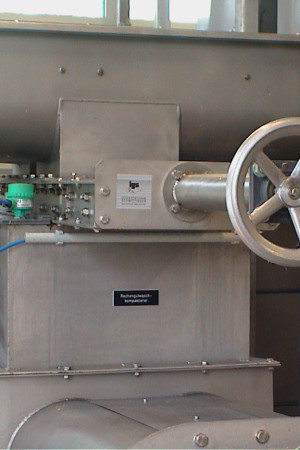

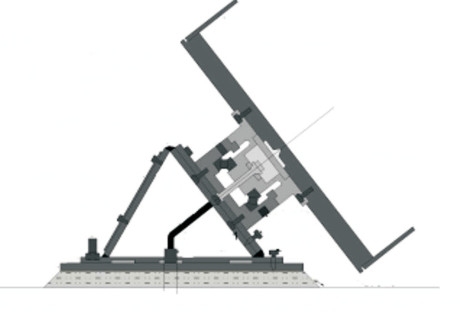

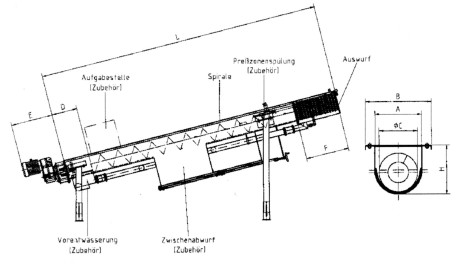

The screenings press is used for the continuous dewatering, compaction, and conveying of screenings. Conveying is achieved by means of an extremely robust conveying and pressing spiral with a length of up to 10 m. The conveying spiral ends in a pressing zone enclosed by a perforated pressing pipe.

With the help of a counter-pressure cone at the end and a conveying spiral that extends only partially into the pressing pipe, the conveyed material forms a friction plug and is compacted while being dewatered.

The pushing drive unit, the shaftless spiral, and the open spiral end ensure clog-free operation.

To reduce wear and extend the service life of the spiral, a plastic wear liner is installed between the stainless steel U-trough and the spiral.

Dewatering Zones and Hygiene

The pre-dewatering zones located along the conveying section of the screw press (e.g., beneath the screen inlets), as well as the dewatering zone at the drive end to protect the bearing and drive unit, are designed in such a way that no brushes or other additional cleaning elements are required, eliminating the need for frequent maintenance and replacements.

For hygienic reasons, the entire length of the machine is covered with bolted lids, except in the area of the feed hopper.

Gallery

Gallery

Downloads

Please contact us directly so that we can provide you with the requested documents and suitable accessories.

Downloads